Read on to discover the right components for system solutions that provide the perfect, proven combination of mobile hydraulics and electronics expertise. The components shown here are used in a variety of applications, including construction machines, cranes, lifting equipment and civil engineering. We have provided links to industry-specific topics and products to make your choice easier. For expert technical advice, prices and delivery times for all the products shown here, please contact our Sales team.

Directional spool valves are a type of directional valve. They control the direction of movement and the velocity of single and double-acting hydraulic consumers. The range includes on/off directional spool valves, proportional directional spool valves and valve combinations.

The proportional directional spool valve type PSL is suitable for constant pump systems, while type PSV is suitable for control pump systems with a pressure/flow controller. The flow rates and load pressures for the individual consumers can be individually adjusted. The proportional directional spool valve types PSL and PSV can be adapted to various control tasks, e.g. for safety functions.

Pmax: 400 bar

Qmax. consumer: 240 lpm

Qpu max: 300 lpm

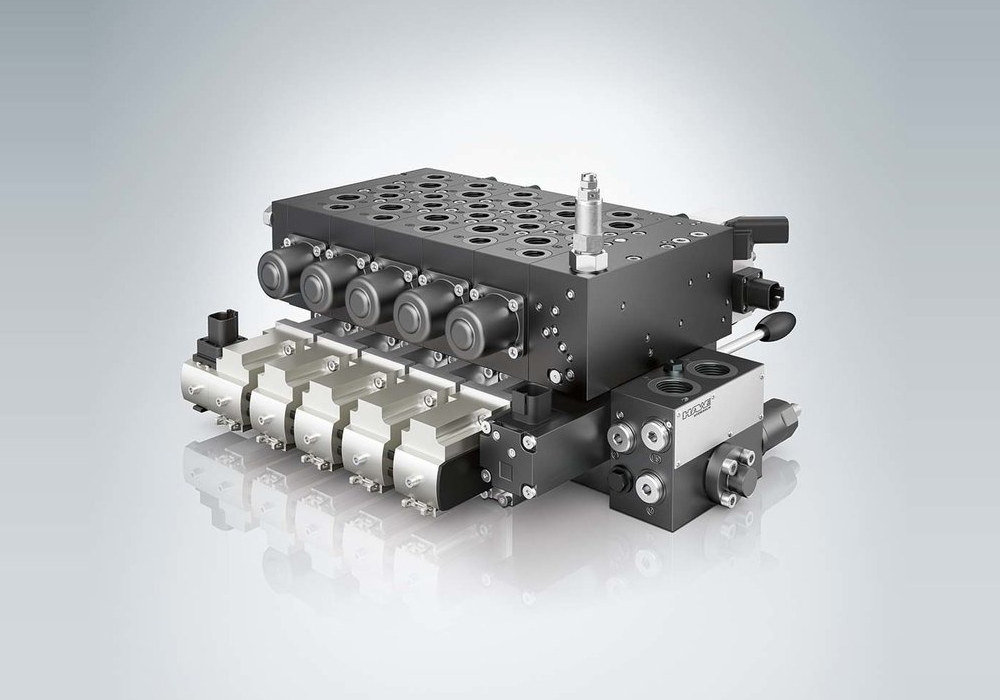

The proportional directional spool valve type PSLF is suitable for constant pump systems, while type PSVF is suitable for control pump systems with a pressure/flow controller. The proportional directional spool valve types PSLF and PSVF are available as individual manifold mounting valves in valve banks. The flow rates and load pressures for the individual consumers can be individually adjusted.

Pmax: 400 bar

Qmax. consumer: 400 lpm

Qpu max: 1000 lpm

The proportional directional spool valve type MICK is a combination of the proportional directional spool valve type PSL and specially designed 8/3-way diverter valves which are flanged-mounted on the PSL sections. The PSL sections proportionally control the flow rate and the downstream diverter valves distribute it to the individual consumers. Up to three dual-acting consumers can thus be supplied with one valve section.

Pmax: 420 bar

Qmax. consumer: 120 lpm

Qmax: 200 lpm

The directional spool valve type EDL with series connection is actuated directly. The flow rates for the individual consumers can be individually adjusted. The proportional directional spool valve can be flexibly adapted to different control tasks by means of additional functions in the intermediate plates and ancillary blocks.

Pmax: 320 bar

Qcons. Max: 48 lpm

Qpu max: 100 lpm

The directional spool valve bank type CWS with series connection is actuated directly. The consumers are black/white controlled. A range of connection blocks and mounted blocks offer a wide range of applications. The valve bank CWS is used mainly in mobile hydraulics. In stationary hydraulics, the direct mounting on the compact hydraulic power pack results in an extremely compact system solution.

Pmax: 315 bar

Qmax: 40 lpm

Load-holding valves are a type of pressure control valve. They prevent loads on cylinders or motors dropping in an uncontrolled manner. For this purpose they are pre-loaded with a pressure setting that is higher than the largest possible load. A hydraulic piston controls the opening of the valve to achieve the required lowering velocity.

The load-holding valve type CLHV is suitable for applications with low and medium tendencies to oscillate and is used especially in connection with proportional directional spool valves, e.g. types PSL and PSV. It is also available with return pressure compensation and spring chamber relief.

Pmax: 350 bar

Qmax: 320 lpm

The type OSCA-D load-holding valve is especially suitable for applications that are either particularly susceptible to vibration or that work with very high load pressures. The valve is designed as a screw-in valve and is easy to install and remove. Choose from a range of connection blocks. Matching tools for producing your own blocks are available.

Pmax: 500 bar

Qmax: 40 lpm

The load-holding valve type LHDV has special damping characteristics. It is suitable for applications that are highly prone to oscillations, and is used especially in connection with proportional directional spool valves, e.g. types PSL and PSV. When the valve is closed, it is completely tight and prevents all leaks. Shock valves and shuttle valves with or without restrictor check valves can be fitted in the load-holding valves, e.g. to relieve hydraulic brakes with a delay.

Pmax: 420 bar

Qmax: 80 lpm

Load-holding valves are a type of pressure control valve. They prevent loads on cylinders or motors dropping in an uncontrolled manner. For this purpose they are pre-loaded with a pressure setting that is higher than the largest possible load. A hydraulic piston controls the opening of the valve to achieve the required lowering velocity.

The axial piston pump type V60N is designed for open circuits in mobile hydraulics and operates on the swash plate principle. It is available with an optional thru-shaft. The pump is fitted mainly to the power take-off on commercial vehicle transmissions. The large selection of different pump controllers allows the type V60N axial piston pump to be used in a variety of applications.

Operating pressure: 400 bar

Peak pressure: 450 bar

Vg max: 130 cm³/rev

The axial piston pump type C40V is designed for open circuits in mobile hydraulics and operates on the swash plate principle. The large selection of different pump controllers allows the axial piston pump type C40V to be used in a variety of applications.

Operating pressure: 280 bar

Peak pressure: 320 bar

Vg max: 85 cm³/rev

The axial piston pump type V30E is designed for open circuits in mobile hydraulics and operates on the swash plate principle. It is available with an optional thru-shaft. The sturdy pump is particularly suitable for continuous operation in challenging applications. The range of pump controllers allows the axial piston pump to be used in a variety of applications.

Operating pressure: 350 bar

Peak pressure: 420 bar

Vg max: 270 cm³/rev

The axial piston pump type V80M is designed for open circuits in mobile hydraulics and operates on the swash plate principle. It is available with an optional thru-shaft. The sturdy pump is particularly suitable for continuous operation in challenging applications. The range of pump controllers allows the axial piston pump to be used in a variety of applications.

Operating pressure: 400 bar

Peak pressure: 450 bar

Vg max: 202 cm³/rev

The axial piston pump type K60N is designed for open circuits in mobile hydraulics and operates on the bent axis principle. The pump is fitted mainly to the power take-off on commercial vehicle transmissions.

Pmax: 400 bar

Vg max: 108 cm³/rev

The axial piston motor type M60N is designed for open and closed circuits and operates based on the bent axis principle. The motor is particularly suitable for usage in mobile applications.

Pmax: 400 bar

Vg max: 130 cm³/rev

Load-holding valves are a type of pressure control valve. They prevent loads on cylinders or motors dropping in an uncontrolled manner. For this purpose they are pre-loaded with a pressure setting that is higher than the largest possible load. A hydraulic piston controls the opening of the valve to achieve the required lowering velocity.

The programmable logic valve control type CAN-IO 14+ is a freely programmable PLC with integrated proportional amplifier. Highly precise functions are possible thanks to the feedback measurement at the valve outputs. The number of digital and analogue inputs and outputs can be configured variably. It also offers a comprehensive range of settings and programming options.

Up to 8 PWM outputs and up to 14 analogue inputs

Flexible programming

Free parametrization of all inputs and outputs

The mobile controller type ESX is a freely programmable PLC with an integrated proportional amplifier. The programming languages LogiCAD, C++ and CoDeSys are available for application programming purposes, depending on the type. The valve control type ESX has been certified according to ISO 13849 (PLd) and ISO 61508 (SIL2). It can be used in safety applications.

Modular system with basic and expansion modules

Flexible programming according to IEC 61131

Different interfaces (CAN, Ethernet, RS232)

Proportional amplifiers actuate proportional solenoid valves by converting an input signal into a corresponding control current. The proportional amplifier type EV2S-CAN is a plug amplifier designed to be fitted directly on a proportional single-stroke or twin solenoid. Parameters can be configured either using the pushbuttons and an integrated display or via CAN bus using computer software.

Control of twin and single valves

Simple diagnostics and status monitoring

Plug amplifier with M12 connection for two solenoid inserts