Fluid control products have been designed to offer customers the ultimate in performance. Every valve is engineered for optimal operation, is constructed with modern machinery that use stringent processes, and provides standard features not necessarily offered in any competitive line. The Fluid Control Series portfolio offers a broad range of 2/2, 3/2 and 5/2 solenoid valves. Sizes range from 1/8” to 3”, with Kv as high as 1385 L/min. Pressure capabilities range up to 200 bar; the whole range is available with various seal materials, such as NBR, FKM, EPDM, PTFE, PCTFE, PUR and Ruby. Brass, Aluminium, Stainless steel and Plastic Valves are available to control a wide variety of air, neutral gases and liquids, water, oils, process fluids and steam.

Modular concept for dedicated valves

D / B Terminal Standard

Various AC / DC voltages

Various IP65-IP67, 100% ED

Meet latest international & national codes

ATEX zone 0, 1, 2, 20, 21, 22 protected ia, ib, dm, d, e, m, me, n

Compact design, high flow rates

Visual position indicator standard

For temperatures from 14°F to 356°F / -10°C to 180°C

Working pressures up to 16 Bar, 232 psi

Dampened closing anti-water hammer design (fluid under seat)

Metal actuator housing for exceptional durability in steam & mildly aggressive applications

Valves satisfy the Pressure Equipment Directive 97/23/EC

Mountable in any position

Tight shut-off and Long Service Life

Valve seats and body gaskets fully repairable

| Body Material | 304 SS or 316 SS |

| Function | 2/2 NC, NO, NC (antiwater hammer), double acting (with spring) |

| Nominal sizes | DN10-DN65, 3/8" to 2" |

| Connections | Threads - BSP.BSPT.NPT.NPTF Welded - ISO1127/4200, DIN 11850.1, DIN 11850.2, DIN 11850.3. SMS3008, ASME BPE Flanges |

| Max Working Pressure | 16 BAR, 232 PSI |

| Pilot Pressure | 3 Bar to 10 Bar. 43.5 PSI to 145 PSI |

| Actuator Material | 304 SS, or Aluminum |

| Maximum Fluid Temp | -10°C to 180°C, 14°F to 356°F |

| Ambient Temperature | -10°C to 60°C, 14°F to 140°F |

| Seat Seal material | PTFE/RTFE |

| Packing Gland | PTFE. PTFE and Carbon |

| Viscosity | Maximum 600mm2/s( 600eSt, 80° E, 2700 SSU |

| Vacuum | Maximum 0.0295 mercury (Hg) |

| Leakage | ANSI Class VI shutoff |

| Installation | Any Position |

| Optical Position Indicator | Standard on all sizes |

| Pilot Control Media | Air, Neutral Gas, Water |

| Fluids handled | Inert gases, hot water, oils, steam, aggressive and corrosive fluids |

| Pilot Port Size | 1/8" for 32,40,50, & 63 mm actuators," for 80, 100 mm actuators |

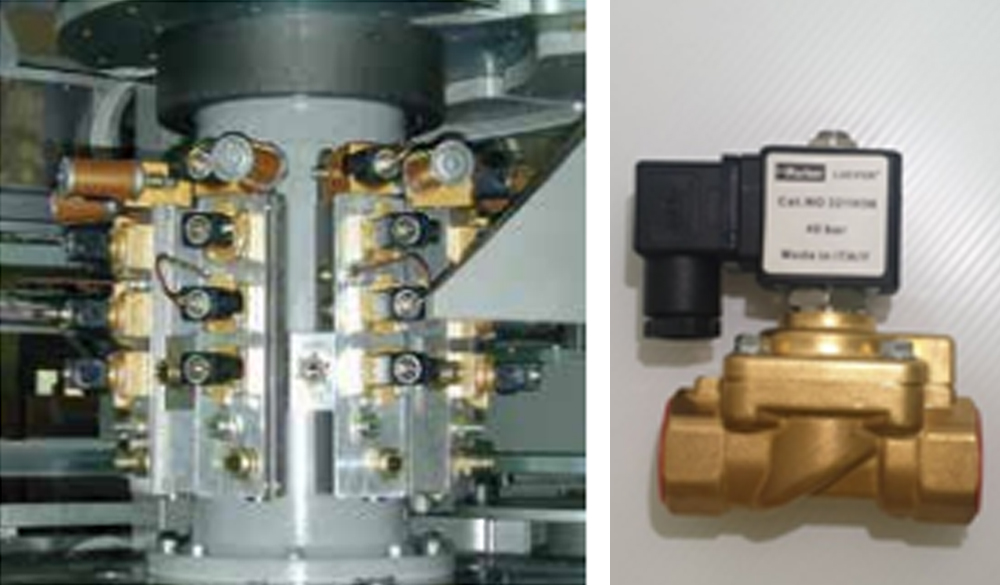

2/2 & 3/2 Solenoid Valves for High Pressure pneumatic applications - 40 bar

2/2 valves and 3/2 way valves - pilot operated

Pipe mounting (G 1/2-3/4) or sub-base mounting

1.5(2) - 40 bar

Normally open or closed

Internal or External pilot pressure supply

Safety of operation

Reliability

Response time stability

Repeatability

No leakage

Integrated non return valve (421 version)

1/4” - 2” pipe mount

Pressure range up to 40 bar

Normally open and normally closed

Direct or servo-acting

Long life expectancy, highest reliability

Manual override optional

Excellent response time

Can be mounted with Lucifer® coil families

1/4” - 1/2” NAMUR interface

Patented NAMUR conversion plate

Highflow Qn: 3000 L/min

Solenoid or pneumatic version

High resistance aluminium

ATEX zone 22 certified products

Fast switching application

1/8” - 1/4” pipe mount and flange version

Pressure range up to 30 bar

Normally open and normally closed, universal

Long life expectancy - highest reliability

Excellent response time repeatability

Can be mounted with Lucifer® coil families

EExPressTM is a stackable system that includes Gateway, Input sensor modules and 5/2 way Solenoid valve modules

EExPressTM uses the well known Profibus DP protocol

IP65 - no cabinet needed

Zone 1, 2, 21 and 22 protection

It has been designed to approach a “plug and play” usage